Top China Manufacturer of Waste Cardboard Packing Machines

As a manufacturer specializing in Waste Cardboard Packing Machines, I understand the challenges businesses face with efficient waste management. Our machines are designed to streamline the packing process, ensuring your cardboard waste is compacted neatly and ready for recycling. Located in China, we pride ourselves on quality and innovation, providing durable solutions that boost your operational efficiency. With our Waste Cardboard Packing Machine, you can reduce labor costs and improve safety in the workplace. This machine takes up minimal space but offers powerful performance, handling large volumes of cardboard waste quickly. Many of our clients have reported significant savings in disposal fees and improved sustainability practices since integrating our product. I’m always here to answer any questions you have and help you find the perfect machine tailored to your needs. Join countless satisfied clients who have transformed their waste management processes and embraced a more eco-friendly approach with our reliable packing solutions.

Waste Cardboard Packing Machine Products Guarantees Peak Performance

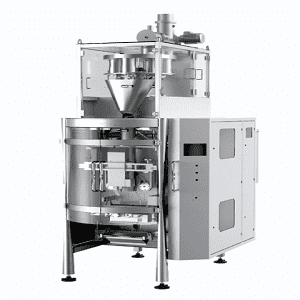

In today's fast-paced manufacturing environment, maximizing efficiency and minimizing waste are critical for businesses aiming to stay competitive. Waste cardboard packing machines have emerged as vital tools for companies looking to streamline their packaging processes while ensuring sustainability. These machines not only optimize the handling of cardboard waste but also contribute significantly to cost savings and environmental responsibility. By investing in advanced packing technology, businesses can guarantee peak performance and enhance their overall operational capabilities. The innovative design of waste cardboard packing machines allows for quick and efficient processing of material, reducing the time and labor associated with traditional packing methods. Features such as automatic feeding, baling, and compacting ensure that businesses can handle high volumes of waste cardboard with ease. Furthermore, the adaptability of these machines makes them suitable for various industries, allowing global buyers to achieve tailored solutions that meet their specific production needs while promoting a greener approach to waste management. By choosing reliable waste cardboard packing machines, companies not only invest in superior performance but also foster a culture of sustainability. This commitment to reducing waste and improving processes can enhance brand reputation and attract environmentally-conscious consumers. As industries around the globe continue to prioritize efficiency and sustainability, investing in these state-of-the-art packing solutions will undoubtedly provide a competitive edge and contribute to long-term success.

Waste Cardboard Packing Machine Products Guarantees Peak Performance

| Product Model | Machine Type | Power (KW) | Processing Speed (pcs/h) | Dimensions (mm) | Weight (kg) |

|---|---|---|---|---|---|

| Model A1 | Semi-Automatic | 5.5 | 300 | 1500 x 800 x 1200 | 600 |

| Model B2 | Fully Automatic | 7.5 | 600 | 1800 x 900 x 1400 | 800 |

| Model C3 | Desktop | 3.0 | 200 | 800 x 600 x 700 | 150 |

| Model D4 | Heavy Duty | 10.0 | 800 | 2000 x 1000 x 1600 | 1200 |

Related Products