Top China Manufacturer of Healthy Tea Packaging Machines for Optimal Efficiency

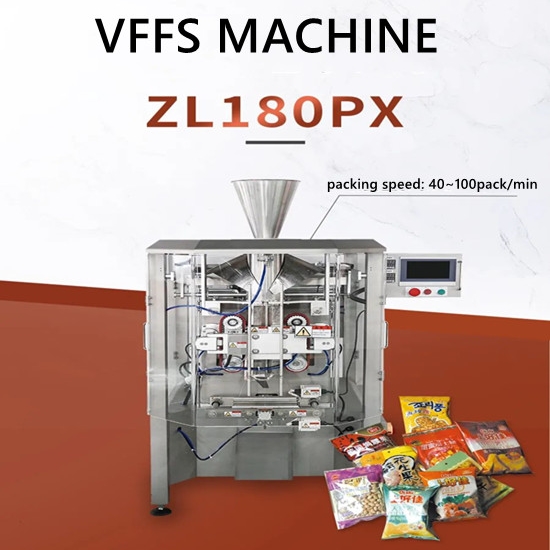

When it comes to packaging healthy tea, I know that quality and efficiency are key. Our Healthy Tea Packaging Machine is designed with precision and versatility in mind, making it the perfect choice for businesses in the expanding tea market. Manufactured in China, this machine ensures that your product maintains its freshness and flavor while being packaged efficiently. I appreciate how easy it is to operate and customize for various packaging styles, whether you need bags, pouches, or something unique. The advanced technology used in our machinery maximizes productivity without compromising on quality, setting you apart from your competition. Partnering with a reliable manufacturer like us means you’re investing in a machine that not only meets your needs but also supports sustainable practices. Let’s elevate your tea business together with our top-notch packaging solutions tailored specifically for the health-conscious consumer.

Healthy Tea Packaging Machine Dominates Ahead of the Curve

In an era where health-conscious consumers are driving the demand for natural products, the packaging of healthy tea has become pivotal for businesses aiming to capture market share. The integration of advanced technology in packaging machinery is enabling producers to meet high standards of quality and efficiency. With a wave of innovation sweeping through the industry, companies are increasingly turning towards automated packaging solutions that not only enhance productivity but also ensure the preservation of flavor and nutritional value. These state-of-the-art machines offer features such as precise volume control, eco-friendly materials, and customizable packaging formats that cater to diverse consumer preferences. By prioritizing sustainability in their manufacturing processes, businesses can appeal to a growing demographic that values environmentally friendly products. Investing in reliable packaging machinery empowers tea producers to stand out in a competitive landscape, providing them with the tools necessary to deliver fresh, high-quality products that resonate with today's health-oriented consumers. As the global market continues to evolve, staying ahead of packaging trends is crucial for those in the tea industry. Implementing cutting-edge technology not only boosts efficiency but also fortifies brand reputation, as it demonstrates a commitment to quality and responsiveness to market needs. Embracing these advancements is not just about keeping up; it's about leading the charge towards a healthier, more sustainable future in tea consumption.

Healthy Tea Packaging Machine Dominates Ahead of the Curve

| Feature | Description | Benefits | Market Trends |

|---|---|---|---|

| Automatic Filling | Enhances production efficiency by automating the filling process of tea. | Reduces labor cost and minimizes human error. | Increased demand for automation in food and beverage industry. |

| Multi-Functionality | Capable of packaging various types of tea products including loose leaf, tea bags, and herbal blends. | Flexibility to meet diverse consumer preferences. | Trend towards personalized and customized tea products. |

| Sustainability Features | Utilizes eco-friendly materials in packaging. | Attracts environmentally conscious consumers. | Growing awareness and demand for sustainable packaging solutions. |

| User-Friendly Interface | Easy to operate and set up with an intuitive control panel. | Reduces training time for new staff. | Focus on consumer experience and operational efficiency. |

| Compact Design | Space-saving model suitable for smaller production facilities. | Makes it accessible for startups and small businesses. | Increase in small-scale artisanal tea producers. |

Related Products

.jpg)