Quality Inspection for Liquid Chlorine Filling Machine - DLS06 – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

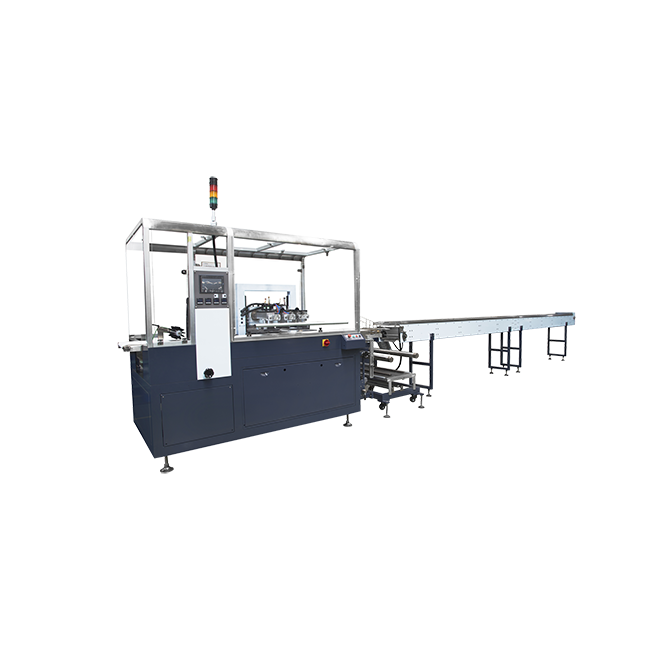

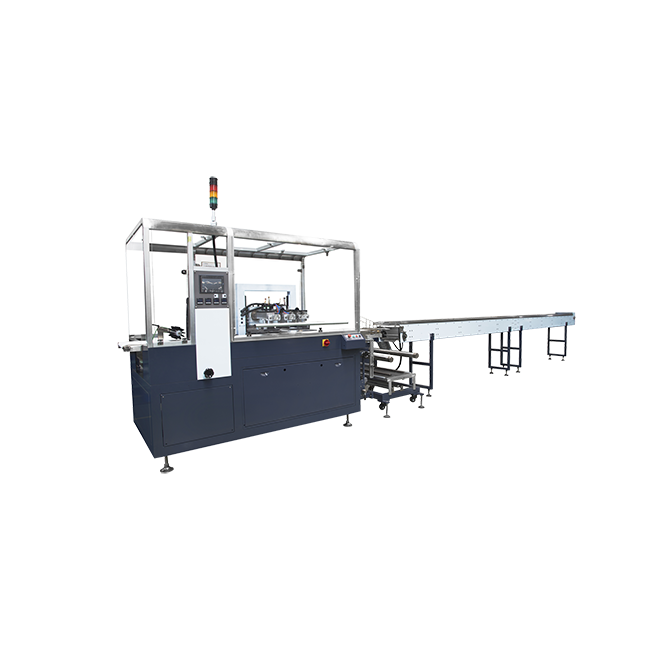

Quality Inspection for Liquid Chlorine Filling Machine - DLS06 – Soontrue Detail:

Main characteristics & Structure features:

1. The servo control system is used for raising and lowering the horizontal sealing bar, which improves packing capacity, and enables easy change of the bag length by simply setting numeric data.

2. The weighing-table is controlled by servo motor, which a small synchronous adjustment can be performed by simply setting numeric data.

3. Product data memory function is used for simple operation. When changing product sizes, the bag length can be easily changed by setting product serial number.

4. Combined with finished products managing device, cartooning machine can form the complete production line.

5. Coordinated with many measuring and filling devices such as auger and volumetric cup filling device for accurate measurement.

Product detail pictures:

Related Product Guide:

Gold, silver, and bronze: A winning design for an athleteâs beverage | Lentil Packing Machine Price

Taline Gabriel reveals which containers she uses to organise pantry | Chemical Seasoning Pouch Packing Machine

It is a great way to further improve our products and repair. Our mission is always to create innovative products to prospects with a superior expertise for Quality Inspection for Liquid Chlorine Filling Machine - DLS06 – Soontrue, The product will supply to all over the world, such as: Marseille, Toronto, Norway, We accomplish this by exporting our wigs directly from our own factory to you. The goal of our company is to get customers who enjoy coming back to their business. We sincerely hope to cooperate with you in the near future. If there's any opportunity, welcome to visit our factory!!!

The company has a good reputation in this industry, and finally it tured out that choose them is a good choice.

Send your message to us:

RELATED PRODUCTS

-

18 Years Factory Shrink Film Packaging Machine ...

-

Manufactur standard Charcoal Briquette Packing ...

-

Well-designed Milk Pouch Packing Machine - HIG...

-

Factory made hot-sale Bolt Packing Machine - H...

-

Manufacturing Companies for Sesame Powder Packi...

-

High Quality for Corrugated Box Making Machine ...