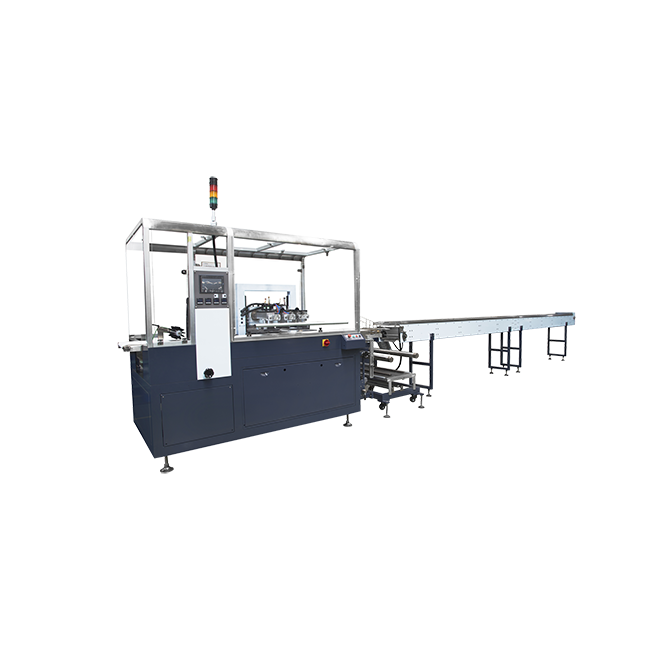

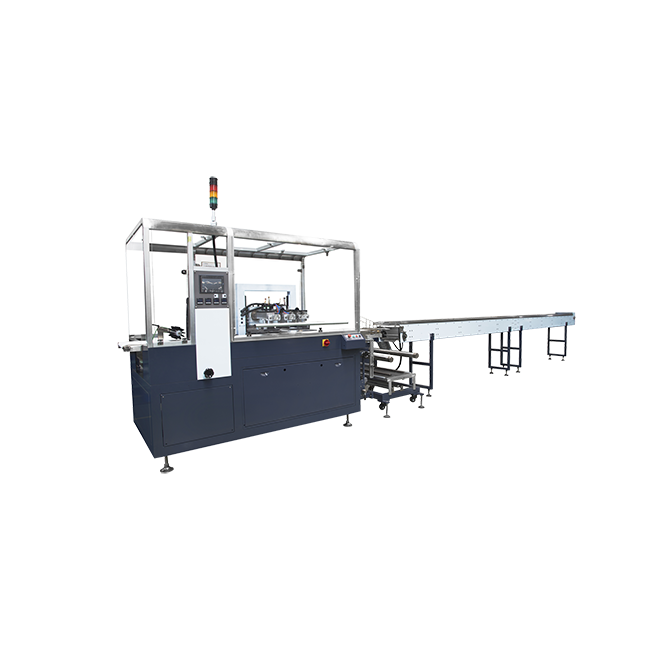

Professional China Paper Straw Packing Machine - DLS06 – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

Professional China Paper Straw Packing Machine - DLS06 – Soontrue Detail:

Main characteristics & Structure features:

1. The servo control system is used for raising and lowering the horizontal sealing bar, which improves packing capacity, and enables easy change of the bag length by simply setting numeric data.

2. The weighing-table is controlled by servo motor, which a small synchronous adjustment can be performed by simply setting numeric data.

3. Product data memory function is used for simple operation. When changing product sizes, the bag length can be easily changed by setting product serial number.

4. Combined with finished products managing device, cartooning machine can form the complete production line.

5. Coordinated with many measuring and filling devices such as auger and volumetric cup filling device for accurate measurement.

Product detail pictures:

Related Product Guide:

Free range is a con. There’s no such thing as an ethical egg | Chas Newkey-Burden | Opinion | Chemical Seasoning Pouch Packing Machine

Historian David Starkey brands Question Time an ‘embarrassment’ | Lentil Packing Machine Price

We have been committed to offering easy,time-saving and money-saving one-stop purchasing service of consumer for Professional China Paper Straw Packing Machine - DLS06 – Soontrue, The product will supply to all over the world, such as: Peru, Ukraine, Japan, By adhering to the principle of "human oriented, winning by quality", our company sincerely welcomes merchants from at home and abroad to visit us, talk business with us and jointly create a brilliant future.

Factory equipment is advanced in the industry and the product is fine workmanship, moreover the price is very cheap, value for money!

Send your message to us:

RELATED PRODUCTS

-

Wholesale Price China Coffee Bag Packing - SZ1...

-

Factory Free sample 15ml Olive Oil Packing Mach...

-

OEM Supply Pre-Made Bag Packing Machines - AUT...

-

OEM/ODM Factory Spout Pouch Filling Machine - ...

-

factory Outlets for Plastic Bag Water Packaging...

-

Good User Reputation for Opp Bag Packing Machin...