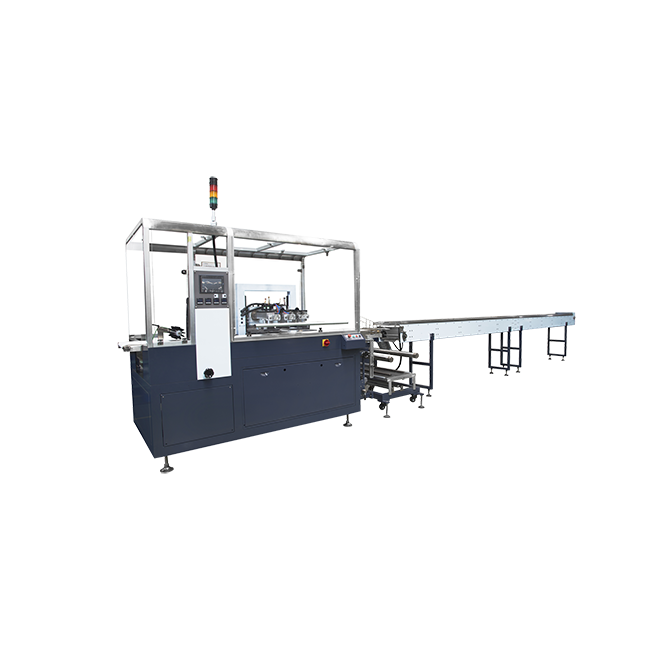

OEM Supply Pre-Made Bag Packing Machines - flour powder and ingredient powder pre-made bag packing machine with dust removing function – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

OEM Supply Pre-Made Bag Packing Machines - flour powder and ingredient powder pre-made bag packing machine with dust removing function – Soontrue Detail:

| Model: | GDR-100E |

| Packing speed | 6-65 Bags/min |

| Bag size | L120-360mm W90-210mm |

| Packing formart | Bags (flat bag, stand bag, zipper bag, hand bag, M bag etc irregular bags) |

| Power type | 380V 50Hz |

| General power | 3.5kw |

| Air consumption | 5-7kg/cm² |

| Packing material | Single layer PE, PE complex film etc |

| Machine weight | 1000kg |

| Outside dimensions | 2100mm*1280mm*1600mm |

1 The whole machine is a ten-station structure, and its operation is controlled by PLC and large-screen touch screen, so it is easy and convenient to operate

2 Automatic fault tracking and alarm system, real-time display of operation status;

3 Mechanical empty bag tracking and detecting device can realize no bag opening, no blanking and no sealing;

4The main drive system adopts variable frequency stepless speed regulation control and full CAM drive, with stable operation and low failure rate (the sealing adopts CAM drive, which will not lead to unqualified sealing due to unstable air pressure);

5 Replacement of product specifications with a key replacement, better improve work efficiency.

6The parts of the machine that come into contact with materials or packaging bags are processed with stainless steel or other materials that meet the requirements of food hygiene to ensure the hygiene and safety of food.

7With liquid mixing device, to prevent the precipitation of micro - particle materials, with liquid level control device.

8The whole machine design conforms to the national GMP standard and has passed the CE certification

Auger scale

● Feature

This type can do dosing and filling work. Due to the special professional design, it is suitable for the fluidity or low-fluidity materials, like milk powder, Albumen powder, rice powder, coffee powder, solid drink, condiment, white sugar, dextrose, food additive, fodder, pharmaceuticals, agriculture pesticide, and so on.

|

Hopper |

Split hopper 25L |

|

Packing Weight |

1 - 200g |

|

Packing Weight |

≤ 100g, ≤±2%; 100 – 200g, ≤±1% |

|

Filling speed |

1- 120 次/分钟,40 – 120 times per min |

|

Power supply |

3P AC208-415V 50/60Hz |

|

Total Power |

1.2 Kw |

|

Total Weight |

140kg |

|

Overall Dimensions |

648×506×1025mm |

Auger lifter

| Speed |

3m3/h |

| Feeding pipe diameter |

Φ114 |

| Machine power |

0.78W |

| Machine weight |

130kg |

| Material box volume |

200L |

| Material box of voulme |

1.5mm |

| Round tube wall thickness |

2.0mm |

| Spiral diameter |

Φ100mm |

| Pitch |

80mm |

| Blade thickness |

2mm |

| Shaft diameter |

Φ32mm |

| Shaft wall thickness |

3mm |

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

Foods you should NEVER eat if you want a flat stomach including ‘healthy’ lentils | Lentil Packing Machine Price

Gemma Collins rocks sequin minidress as she cosies up to beau James Argent at ITV gala | Automatic Powder Packing Machine

We stick to our enterprise spirit of "Quality, Efficiency, Innovation and Integrity". We aim to create more value for our customers with our rich resources, advanced machinery, experienced workers and excellent services for OEM Supply Pre-Made Bag Packing Machines - flour powder and ingredient powder pre-made bag packing machine with dust removing function – Soontrue, The product will supply to all over the world, such as: Qatar, Montreal, Greece, If you have any requests, pls email Us with your detailed demands, we will give you the most wholesale Competitive Price with the Super Quality and the Unbeatable First-class Service ! We can give you the most competitive prices and high quality, because we are much more PROFESSIONAL! So please do not hesitate to contact us.

This company has a lot of ready-made options to choose and also could custom new program according to our demand, which is very nice to meet our needs.

Send your message to us:

RELATED PRODUCTS

-

Good Wholesale Vendors Stick Pouch Packing Mach...

-

PriceList for Multifunctional Water Filling Mac...

-

Fixed Competitive Price Shrink Package Machine ...

-

OEM/ODM Supplier Bread Dough Packing Machine -...

-

Newly Arrival Biscuit Packing Machine Price - ...

-

Best Price for Automatic Vertical Cartoning Mac...