OEM China Made Bag Packing Machine For Powder - FLAT BOTTOM BAG PACKAGING MACHINE OF STAND UP QUAD SEAL FOR MIXED NUTS PACKING MACHINE – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

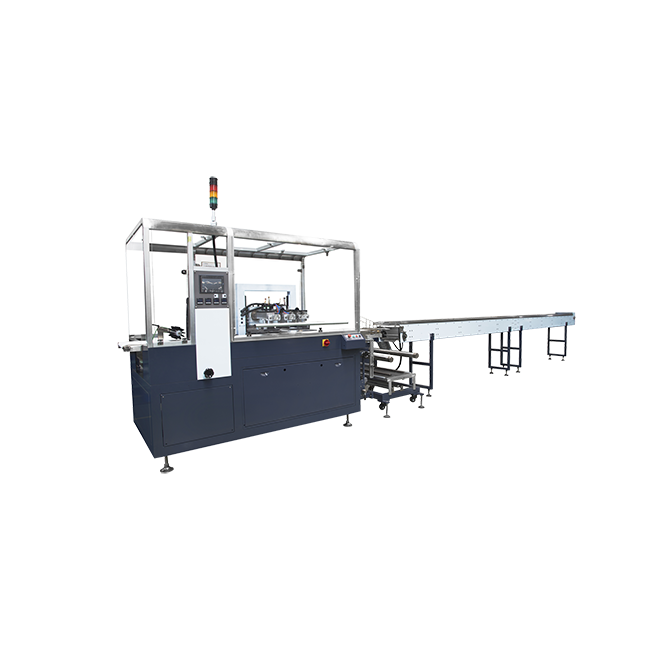

OEM China Made Bag Packing Machine For Powder - FLAT BOTTOM BAG PACKAGING MACHINE OF STAND UP QUAD SEAL FOR MIXED NUTS PACKING MACHINE – Soontrue Detail:

| Model: | GDR-100K |

| Packing speed | 6-45 Bags/min |

| Bag size | L120-400mm W150-300mm |

| Packing formart | Bags (flat bag, stand bag, zipper bag, hand bag, M bag etc irregular bags) |

| Power type | 1 PH 220V, 50Hz |

| General power | 3.5kw |

| Air consumption | 5-7kg/cm² 500L/min |

| Packing material | Single layer PE, PE complex film etc |

| Machine weight | 1000kg |

| Outside dimensions | 2300mm*1600mm*1600mm |

1. The machine with ten-station structure, running by PLC, big touch screen centralized control, easy operation;

2. Automatic fault tracking and detection device, to achieve no bag opening, no filling and no sealing;

3. Mechanical empty bag tracking and detection device, to achieve no bag opening, no filling and no sealing;

4. The main drive system adopts variable frequency speed control, full CAM drive, running smoothly, low failure rate;

5 The design of the whole machine conforms to GMP standard and has passed CE certification.

10 HEADS WEIGHER

● Features

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

| Item | Standard 10 multi head weigher |

| Generation | 2.5G |

| Weighing range | 15-2000g |

| Accuracy | ±0.5-2g |

| Max speed | 60WPM |

| Power supply | 220V , 50HZ, 1.5KW |

| Hopper volume | 1.6L/2.5L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1436*1086*1258 |

| 1436*1086*1388 |

Z-TYPE CONVEYOR

● Features

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

● Specification

| Model | ZL-3200 HD |

| Bucket hopper | 1.5 L |

| Capacity(m³h) | 2-5 m³h |

| Bucket material | PP Food Gradewe have developed dozens of bucket molds ourselves |

| Bucket style | Slippy bucket |

| Framework material | Sprocket: Mild steel with chrome coatingAxis: Mild steel with nickel coating |

| Dimension | Machine height 3100*1300 mmStandard export case 1.9*1.3*0.95 |

| Optional parts | Frequency converterSensorPan for leakage product |

| The material and brand of the internal parts of the machine can be specified , and it can be be selected according to the product and service environment of the machine | |

SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

Full Automatic Tablet Packing Machine Market Top Key Players to 2025 by Type, Application and Region | Lentil Packing Machine Price

Blister Packaging Equipment Market CAGR of 5.4% during 2017 â 2025 to reach US$3,261.6 mn by 2025 | Packaging Update : Marchesini Group S.p.A.. Bosch Packaging Technology, IMA Industria Macchine Automatiche S.p.A., Körber AG | Automatic Powder Packing Machine

We have a highly efficient team to deal with inquiries from customers. Our goal is "100% customer satisfaction by our product quality, price & our team service" and enjoy a good reputation among clients. With many factories, we can provide a wide range of OEM China Made Bag Packing Machine For Powder - FLAT BOTTOM BAG PACKAGING MACHINE OF STAND UP QUAD SEAL FOR MIXED NUTS PACKING MACHINE – Soontrue, The product will supply to all over the world, such as: Hongkong, Saudi Arabia, Muscat, Our company warmly invites domestic and overseas customers to come and negotiate business with us. Allow us to join hands to create a brilliant tomorrow! We've been looking forward to cooperating with you sincerely to achieve a win-win situation. We promise to try our best to deliver you with high quality and efficient services.

We are long-term partners, there is no disappointment every time, we hope to maintain this friendship later!