| Model: | ZL180PX |

| Bag size | Laminated film |

| Average speed | 20-100 bags/min |

| Packing film width | 120-320mm |

| Bag size | L 50-170 mm W 50-150mm |

| Film material | PP.PE.PVC.PS.EVA.PET.PVDC+PVC.OPP+Complex CPP |

| Air consumption | 6kg/㎡ |

| General power | 4kw |

| Main motor power | 1.81kw |

| Machine weight | 350kg |

| Power supply | 220V 50Hz.1Ph |

| Outside dimensions | 1350mm*1000mm*2350mm |

1. The whole machine use 3 servo control system, running stability, high accuracy, fast speed, lower noisy.

2. It adopt touch screen operate, more easy, more intelligent.

3.Various packing type: pillow bag, punch hole bag, connect bags etc.

4. This machine can equip with multi-head weigher , electrical weigher, volume cup etc.

5. Entire machine design is more optimized for more convenient operation.

6. SS304 machine frame with sand blasted treatment realizes nice appearance.

7. Key components are specially designed, fast packing speed.accuracy is more flexible for packing different products.

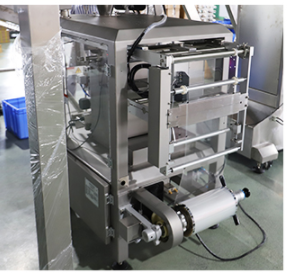

Film loader

servo film-pulling and film loading assembly with dancing arm moves up and down, realizing dynamic control of the film tension. film travels above eye mark sensor, realizing precise film tracking and positioning.

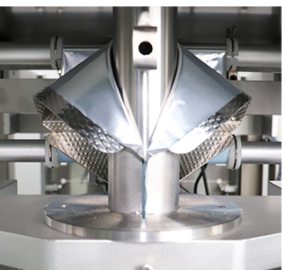

Bag former

Drawn down by servo drive friction pull-down belt, packing film enters to bag former,

Realizing nice and neat packaging performance. With user-friendly design, it is easy to change the bag former for different film width.

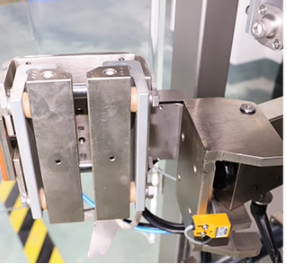

Mid-sealing assembly

Cylinder control mid sealing assembly, with independent temperature control, realizing precise and nice sealing appearance.

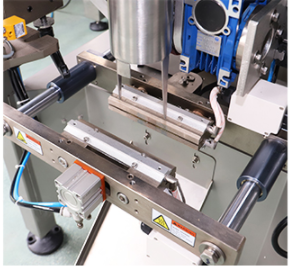

End sealing assembly

Servo control end sealing jaws move in open-close motion, with independent temperature control. Heated sealing jaws will make top seal of one bag and bottom seal of next bag at the same time. Then finished pillow bag will be discharged.

Intuitive HMI display

Different settings for set up, commissioning, daily operation and maintenance can be conducted via the touch screen. With memory function, easy for different packing size change over.

Electric control box

Enclosure material is made from stainless steel. Cables are in a well-organized and efficient way with cable trays and ducts. All cables are labeled clearly, which is easy for connection and maintenance.