In the fast-paced world of manufacturing and food processing, efficiency and precision are critical. One of the most significant advances in this field has been the development of the vertical packaging machine. This innovative equipment is designed to simplify the packaging process, ensuring that products are packed safely and efficiently, while also being able to accommodate a variety of packaging formats. In this blog, we will explore the functions and benefits of the vertical packaging machine, focusing on its unique features and the technology that drives it.

Learn about vertical packaging machines

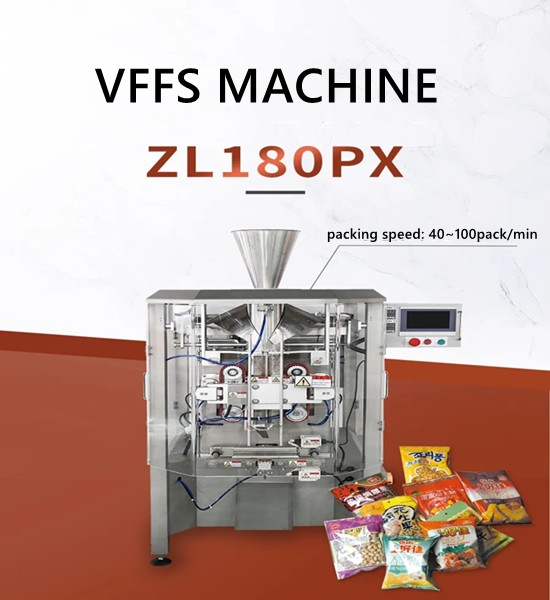

Vertical packaging machines are specialized equipment used to package products vertically. They are particularly popular in industries such as food, pharmaceuticals, and consumer goods where speed and accuracy are critical. Designed to handle a wide range of products from granules and powders to liquids and solids, these machines are extremely versatile.

One of the outstanding features of modern vertical packaging machines is their advanced control system. Many of these machines use single-axis or dual-axis servo control systems to provide precise control of the packaging process. This technology allows different film pulling structures to be selected according to the specific characteristics of the packaging materials used, including single film pulling and double film pulling. This adaptability ensures that the machine can handle a variety of materials without compromising quality or efficiency.

Main features of vertical packaging machine

1.Servo Control System: The integration of single-axis and dual-axis servo control systems improves the precision of the packaging process. These systems enable the machine to adjust its operation according to the type of material used, ensuring optimal performance.

2.Film traction structure: Vertical packaging machines can be configured to use single or double film traction structures. This flexibility is critical to accommodate different types of packaging materials, as packaging materials may require different levels of tension and control during the packaging process.

3.Vacuum Film Stretch System: For products that are sensitive to movement or require gentle handling, the vacuum film stretch system is an excellent choice. This system uses vacuum technology to hold the film firmly in place, minimizing the risk of product damage during the packaging process.

4.Multi-functional packaging formats: One of the most significant advantages of vertical packaging machines is the ability to produce a variety of packaging formats. These machines can produce pillow bags, side ironing bags, gusseted bags, triangular bags, punched bags, and continuous bag types. This versatility makes it suitable for a variety of products and industries.

5.User-friendly interface: Modern vertical packaging machines are equipped with intuitive control panels that make it easy for operators to set up and adjust the machine. This user-friendly design shortens the learning curve and allows for quick switching between different packaging formats.

Benefits of using a vertical packaging machine

1.Improve efficiency: The vertical packaging machine is designed for high-speed operation, which can greatly reduce the time required for packaging. The improvement in efficiency can increase productivity and reduce labor costs.

2.Improved Product Quality: The precision provided by the servo control system ensures that products are packaged consistently and safely. This attention to detail helps maintain product integrity and reduces the possibility of damage during shipping.

3.Cost-effective: Vertical packaging machines can save manufacturers a lot of money by streamlining the packaging process and reducing waste. Being able to handle multiple packaging formats also means that companies can invest in one machine instead of multiple dedicated machines.

4.Flexibility: The adaptability of vertical packaging machines enables manufacturers to quickly respond to changing market demands. Whether launching new products or adjusting packaging formats, these machines can be easily reconfigured to meet specific needs.

5.Enhanced Safety: Vertical packaging machines have features such as vacuum suction and precise control to minimize the risk of accidents and injuries during the packaging process. This focus on safety is essential to maintaining an efficient and safe working environment.

In summary, vertical packaging machines represent a significant advancement in the packaging industry. They combine advanced technology, versatility, and efficiency, making them a valuable asset for manufacturers seeking to optimize their packaging processes.

Post time: Nov-27-2024