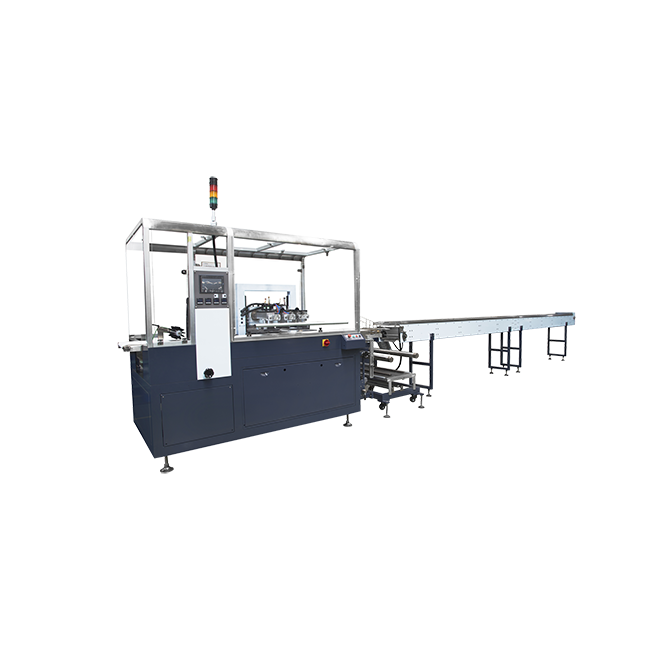

Hot Sale for Capsule Filling Machine - VFFS HIGH SPEED PACKING MACHINE WITH MULTI HEAD WEIGHER PACKING MACHINE FOR MELON SEEDS AND DATES PACKAGING ZL180A – Soontrue Detail:

Applicable

It is suitable for automatic packaging of granular strip, sheet, block, ball shape, powder and other products. Such as snack, chips, popcorn, puffed food,dried fruits, cookies, biscuits, candies, nuts, rice,beans, grains, sugar, salt, pet food, pasta, sunflower seeds, gummy candies, lollipop, Sesame.

Product Advantage

1. Simple system structure is composed of three sets of servo drivers, servo motor and touch screen. Servo driver built-in motion control function, no need independent PLC controller. All connectors can insert directly, compact structure design, easy to install and maintain, with high cost performance.

2. The appearance and operation interface of the machine have been optimized and improved by the professional design group, conforms to the concept of “human-machine interaction”.

3. The machine is fully intelligent, easy to operate, no need debugging, start the machine and you can use it.Every staff without experience easy to learn quickly under the instruction of the professional. The basic parameters only packing speed and length, other parameters can be adjusted on the computer in time.

Main characteristics & Structure features

1 .The machine is an eight-station structure, and its operation is controlled by PLC and large-screen touch screen, which is easy and convenient to operate.

2. Automatic fault tracking and alarm system, real-time display of operation status;

3. Mechanical empty bag tracking and detection device realizes no bag opening, no blanking and no sealing;

4. The main drive system adopts variable frequency step less speed regulation control and full CAM drive, with stable operation and low failure rate;

5 .Replacement of product specifications with a key replacement, better improve work efficiency.

6 .The parts of the machine that come into contact with materials or packaging bags are processed with stainless steel or other materials that meet the requirements of food hygiene to ensure the hygiene and safety of food.

7 .The whole machine design conforms to the national GMP standard and has passed the CE certification.

Product detail pictures:

.jpg)

.jpg)

.jpg)

Related Product Guide:

Global Pharmacy Repackaging Systems Market – Industry Analysis, Size, Share, Growth, Trends, and Forecast 2018 – 2026 | Lentil Packing Machine Price

Macro and Microeconomic Factors Continue to Impact Side Sealer Machines Market During 2018 | Automatic Powder Packing Machine

we are able to provide good quality items, aggressive rate and best shopper assistance. Our destination is "You come here with difficulty and we provide you with a smile to take away" for Hot Sale for Capsule Filling Machine - VFFS HIGH SPEED PACKING MACHINE WITH MULTI HEAD WEIGHER PACKING MACHINE FOR MELON SEEDS AND DATES PACKAGING ZL180A – Soontrue, The product will supply to all over the world, such as: Cambodia, Zimbabwe, Gambia, With the enterprising spirit of" high efficiency, convenience, practicality and innovation", and in line with such serving guidance of "good quality but better price, " and "global credit", we've been striving to cooperate with the automobile parts companies all over the world to make a win-win partnership.

We are a small company that has just started, but we get the company leader's attention and gave us a lot of help. Hope we can make progress together!