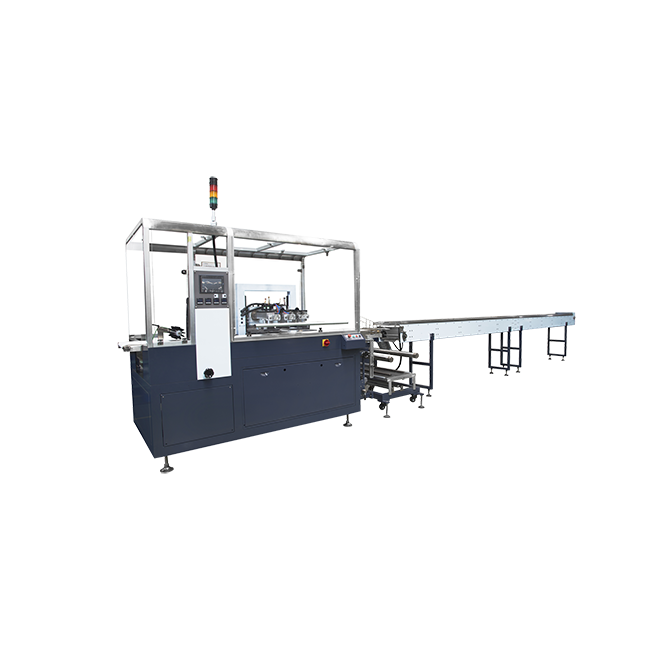

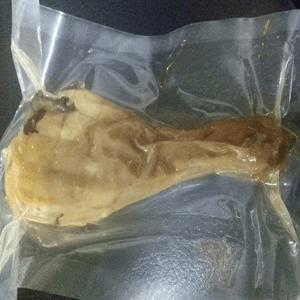

Excellent quality Rotary Pre-Made Bag Packing Machine - AUTOMATIC ROTARY PREMADE POUCH CHICKEN FISH FROZEN FRESH FOOD VACUUM PACKING MACHINE – Soontrue Detail:

| Model: | GDR-160E |

| Machine Material | Food contact use stainless steel 304, other part use sanitary standard material |

| Vacuum Pump | Germany Busch 63 pump/2kw, Shanghai Zong De 63 pump/1.5kw |

| Pneumatic Component | Japan SMC (Standard); TaiWan AirTAC (Not standard) |

| Drive Mode | Variable frequency and variable speed motor driving (Japan FUji) |

| Suitable product | Sunflower seeds, peanuts, walnut and so on (Based on customer require ments) |

| Filling range | 10g-1000g |

| Work Flow | Send bags, code printing , open bags, drop product 1, drop product 2, straighten ,transfer to vacuum position |

| Sealing type | Instant heat sealing , after sealing instant cooling |

| Packing speed | 35-60 bags/min |

| Pre-made bag material | Aluminum film bag, paper bag, Nylon bag etc lamination bag |

| Packing size range | Length 80-200mm Width 80-160mm |

| Total power | Main machine power 5.5kw |

| Machine outer dimension | 2100mm*1400mm*1600mm |

| Main machine weight | 2.2Ton |

| Environment conditions | Indoor temperature 10-40 ℃. 30-90%RH, No corrosive gas, No dust etc |

1. The machine main transmission system adopt variable frequency control, stepless speed regulation. All cam transmission. Compare with cylinder machine type, this machine structure is more tight. When change different specification product, can though touch screen, just press one button can change the bag size.

2 . The machine is stable during long time running. Very low failure rate. Low maintains cost. Compare with cylinder packing machine type, cylinder machine one year parts maintain fees is around RMB 10000. Soonture cam maintain fees is around RMB 1000. Its save money and more stability.

3. The machine is easy to operate.

5. The whole machine total power is 5.5KW, compare with cylinder machine total power is 6-8KW, it energy-saving.

6. The whole machine precision structure, low noisy.

10 HEADS WEIGHER

● Features

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

| Item | Standard 10 multi head weigher |

| Generation | 2.5G |

| Weighing range | 15-2000g |

| Accuracy | ±0.5-2g |

| Max speed | 60WPM |

| Power supply | 220V , 50HZ, 1.5KW |

| Hopper volume | 1.6L/2.5L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1436*1086*1258 |

| 1436*1086*1388 |

Z-TYPE CONVEYOR

● Features

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

● Specification

| Model | ZL-3200 HD |

| Bucket hopper | 1.5 L |

| Capacity(m³h) | 2-5 m³h |

| Bucket material | PP Food Gradewe have developed dozens of bucket molds ourselves |

| Bucket style | Slippy bucket |

| Framework material | Sprocket: Mild steel with chrome coatingAxis: Mild steel with nickel coating |

| Dimension | Machine height 3100*1300 mmStandard export case 1.9*1.3*0.95 |

| Optional parts | Frequency converterSensorPan for leakage product |

| The material and brand of the internal parts of the machine can be specified , and it can be be selected according to the product and service environment of the machine | |

SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

Automated Assembly of Medical Devices | 2018-05-01 | Automatic Blister Packing Machine

Indonesia’s first edible food packaging firm reveals automation plan to drive down costs Menu Back to Back to Back to Back to Back to Back to Send Follow us on Facebook Follow us on Twitter Follow us on LinkedIn Send contact Email to a friend Facebook T | Sugar Packing Machine

Our commission should be to provide our end users and clients with very best excellent and aggressive portable digital products and solutions for Excellent quality Rotary Pre-Made Bag Packing Machine - AUTOMATIC ROTARY PREMADE POUCH CHICKEN FISH FROZEN FRESH FOOD VACUUM PACKING MACHINE – Soontrue, The product will supply to all over the world, such as: Georgia, Paraguay, Vietnam, Look forward to the future, we will focus more on the brand building and promotion . And in the process of our brand global strategic layout we welcome more and more partners join us, work together with us based on mutual benefit. Let's develop market by fully utilizing our comprehensive advantages and strive for building.

In general, we are satisfied with all aspects, cheap, high-quality, fast delivery and good procuct style, we will have follow-up cooperation!