CHIPS PACKING MACHINE | SMALL PACKING MACHINE – SOONTRUE

Applicable

It is suitable for automatic packaging of granular strip, sheet, block, ball shape, powder and other products. Such as snack, chips, popcorn, puffed food,dried fruits, cookies, biscuits, candies, nuts, rice,beans, grains, sugar, salt, pet food, pasta, sunflower seeds, gummy candies, lollipop, Sesame.

Product Detail

Video Information

Specification

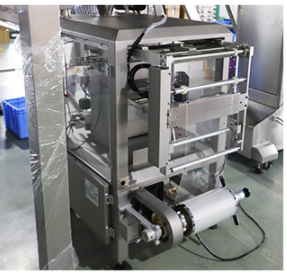

| Model: | ZL200SL |

| Bag size | Complex Film (PP, PE, PVC, PS, EVA, PET, PVDC+PVC, CPP, etc.) |

| Average speed | 20-90 bags/min |

| Packing film width | 220-420mm |

| Bag size | L 50-300 mm W 100-200mm |

| Film material | PP.PE.PVC.PS.EVA.PET.PVDC+PVC.OPP+Complex CPP |

| Air consumption | 6kg/㎡ |

| General power | 4kw |

| Main motor power | 1.81kw |

| Machine weight | 370kg |

| Power supply | 220V 50Hz.1Ph |

| Outside dimensions | 1453mm*1138mm*1480mm |

Main characteristics & Structure features

- The equipment adopts single shaft or double shaft servo control system;

- Horizontal seal system is specially designed for high packing speed;

- The machine can realize various packing type: pillow bag, punching bag, continuous bag, continuous bag with half bag punched;

- The scale is integrated with the frame, with the overall height of 2.35m. It is simple to clean and quick to disassemble;

- The design conforms to GMP standard and has passed CE certificate.

optional accessories

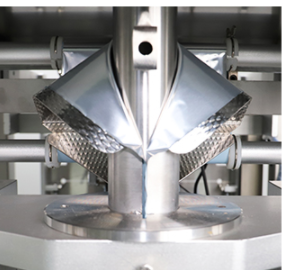

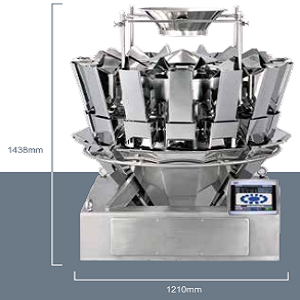

14 HEADS WEIGHER

● Feature

4.0 generation modular control system

Robust design and construction

More than 30 improvements

Full stainless steel machine

| Item | 14 head multihead weigher |

| Generation | 4.0G Basic |

| Weighing range | 15g-1000g |

| Accuracy | ±0.5-2g |

| Max speed | 110 WPM |

| Power supply | 220V 50HZ 1.5KW |

| Hopper volume | 1.6L/3L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1202*1210*1438 |

Z-type lifter

Z-shape Bucket Conveyor(BOX Framework) is Stronger item which is applicable for

vertical lifting of granule and small lumpy product with free flowing such as grain, food,

feed, pills, small plastic, corn, snack, candy, nuts and chemical product,etc. For this machine,

the bucket is driven by chains to convey. Automatic feeding and stopping can be realized

by control circuit and control switch.Precise control of each part process makes the

machine run smoothly with low noise.This machine is assembled by connecting box

sections, each section is welded seamlessly, it is more stable and easy to install and

disassemble.

| Machine | Bucket elevator |

| Bucket Volume | 1L/1.8L/3.8L/6.5L |

| Machine structure | #304 stainless steel or carbon steel.304 |

| Production capacity | 2-3.5 / 4-6 / 6.5-8 / 8.5-12m3/H |

| Machine height | 3896mm for standard (1.8L) |

| Discharge height | 3256mm for standard (1.8L) |

| Hopper material | Food grade PP/ABS |

| Power supply | AC 220V Single phase / 380V, 3 Phase, 50Hz; 0.75kw |

| Packing Dimension | 2050 (L)*1350 (W)*980mm (H) for standard (1.8L) |

Working platform

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

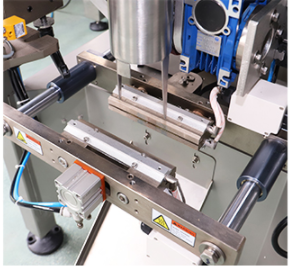

OUTPUT CONVEYOR

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Send your message to us:

RELATED PRODUCTS

Send your message to us:

- English

- French

- German

- Portuguese

- Spanish

- Russian

- Japanese

- Korean

- Arabic

- Irish

- Greek

- Turkish

- Italian

- Danish

- Romanian

- Indonesian

- Czech

- Afrikaans

- Swedish

- Polish

- Basque

- Catalan

- Esperanto

- Hindi

- Lao

- Albanian

- Amharic

- Armenian

- Azerbaijani

- Belarusian

- Bengali

- Bosnian

- Bulgarian

- Cebuano

- Chichewa

- Corsican

- Croatian

- Dutch

- Estonian

- Filipino

- Finnish

- Frisian

- Galician

- Georgian

- Gujarati

- Haitian

- Hausa

- Hawaiian

- Hebrew

- Hmong

- Hungarian

- Icelandic

- Igbo

- Javanese

- Kannada

- Kazakh

- Khmer

- Kurdish

- Kyrgyz

- Latin

- Latvian

- Lithuanian

- Luxembou..

- Macedonian

- Malagasy

- Malay

- Malayalam

- Maltese

- Maori

- Marathi

- Mongolian

- Burmese

- Nepali

- Norwegian

- Pashto

- Persian

- Punjabi

- Serbian

- Sesotho

- Sinhala

- Slovak

- Slovenian

- Somali

- Samoan

- Scots Gaelic

- Shona

- Sindhi

- Sundanese

- Swahili

- Tajik

- Tamil

- Telugu

- Thai

- Ukrainian

- Urdu

- Uzbek

- Vietnamese

- Welsh

- Xhosa

- Yiddish

- Yoruba

- Zulu

- Kinyarwanda

- Tatar

- Oriya

- Turkmen

- Uyghur