China Manufacturer for Function Bag Packing Machine - AUTOMATIC SHIP BISCUIT VACUUM PACKING MACHINE OR COMPRESSED BISCUIT PACKING MACHINE – Soontrue

Product Detail

Video Information

Related Video

Feedback (2)

China Manufacturer for Function Bag Packing Machine - AUTOMATIC SHIP BISCUIT VACUUM PACKING MACHINE OR COMPRESSED BISCUIT PACKING MACHINE – Soontrue Detail:

| Model: | GDR-160D |

| Bag size | L 40-170mm W 30-150mm |

| Vacuum pump | German busch 63 pump 2kw(200) |

| German busch 63 pump 1.5kw (100) | |

| Pneumatic element | Japan SMC |

| Driver mode | frequency control motor drive |

| Filling range | 10g-1000g |

| Packing speed | 35-60 bags/min |

| Packing material | aluminum film bag, paper bag ,nylon bag, |

| Bag type | Stand up pouch,Doypack with zipper,3 side seal bag, 4 side seal bag,flat bag,Spout pouchStand up pouch,Doypack with zipper,3 side seal bag, 4 side seal bag,flat bag,Spout pouch |

| General power | 5kw |

| Outside dimensions | 2100mm*1400mm*1600mm |

| Machine weight | 2.2T |

· 1 The machine is an eight-station structure, and its operation is controlled by PLC and large-screen touch screen, which is easy and convenient to operate.

· 2. Automatic fault tracking and alarm system, real-time display of operation status;

· 3 Mechanical empty bag tracking and detection device realizes no bag opening, no blanking and no sealing;

· 4. The main drive system adopts variable frequency stepless speed regulation control and full CAM drive, with stable operation and low failure rate;

· 5 Replacement of product specifications with a key replacement, better improve work efficiency.

· 6 The parts of the machine that come into contact with materials or packaging bags are processed with stainless steel or other materials that meet the requirements of food hygiene to ensure the hygiene and safety of food.

· 7 The whole machine design conforms to the national GMP standard and has passed the CE certification.

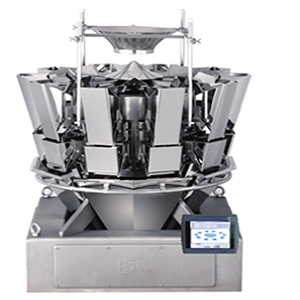

10 HEADS WEIGHER

● Features

1. One of the most economic&stable multi-head weigher in the world the best cost-effective

2. Stagger Dump avoid bigger items pile up

3. Individual feeder control

4. User friendly touch screen equipped with multiple language

5. Compatible with single packaging machine, rotary bagger, cup/bottle machine, tray sealer etc.

6. 99 preset program for multiple tasks.

| Item | Standard 10 multi heads weigher |

| Generation | 2.5G |

| Weighing range | 15-2000g |

| Accuracy | ±0.5-2g |

| Max speed | 60WPM |

| Power supply | 220V , 50HZ, 1.5KW |

| Hopper volume | 1.6L/2.5L |

| Monitor | 10.4 inches color touch screen |

| Dimension (mm) | 1436*1086*1258 |

| 1436*1086*1388 |

Z-TYPE CONVEYOR

● Features

The conveyer is applicable for vertical lifting of grain material in departments such as corn, food, fodder and chemical industry, etc. For the lifting machine,

the hopper is driven by the chains to lift. It’s used for vertical feeding of grain or small block material. It has advantages of large lifting quantity and highness.

● Specification

| Model | ZL-3200 HD |

| Bucket hopper | 1.5 L |

| Capacity(m³h) | 2-5 m³h |

| Bucket material | PP Food Gradewe have developed dozens of bucket molds ourselves |

| Bucket style | Slippy bucket |

| Framework material | Sprocket: Mild steel with chrome coatingAxis: Mild steel with nickel coating |

| Dimension | Machine height 3100*1300 mmStandard export case 1.9*1.3*0.95 |

| Optional parts | Frequency converterSensorPan for leakage product |

| The material and brand of the internal parts of the machine can be specified , and it can be be selected according to the product and service environment of the machine | |

SUPPORTING PLATFORM

● Features

The supporting platform is solid will not affect the measurement accuracy of the combination weigher.

In addition, the table board is to use the dimple plate, it is more secure, and it can avoid slipping.

● Specification

The size of the supporting platform is according to the type of the machines.

● Features

The machine can send the packed finished bag to after-package detecting device or packing platform.

● Specification

| Lifting height | 0.6m-0.8m |

| Lifting capacity | 1 cmb/hour |

| Feeding speed | 30mminute |

| Dimension | 2110×340×500mm |

| Voltage | 220V/45W |

Product detail pictures:

Related Product Guide:

tata group: Tata Group mulls folding food businesses into single company, Retail News, ET Retail | Chemical Seasoning Pouch Packing Machine

The three fastest-growing food plans are revealed | Automatic Blister Packing Machine

Sticking to the belief of "Creating products of high quality and making friends with people from all over the world", we always put the interest of customers in the first place for China Manufacturer for Function Bag Packing Machine - AUTOMATIC SHIP BISCUIT VACUUM PACKING MACHINE OR COMPRESSED BISCUIT PACKING MACHINE – Soontrue, The product will supply to all over the world, such as: Portugal, Guinea, Finland, Many goods fully conform to the most rigorous of international guidelines and with our first-rate delivery service you will have them delivered at any time and in any place. And because Kayo deals in the entire spectrum of protective equipment, our customers don't have to waste time shopping around.

Hope that the company could stick to the enterprise spirit of "Quality, Efficiency, Innovation and Integrity", it will be better and better in the future.

Send your message to us:

RELATED PRODUCTS

-

Good quality Preforming Bag Packing Machine - ...

-

High definition Tomato Paste Sachet Packing Mac...

-

professional factory for Pre Made Bag Milk Powd...

-

China wholesale Pre-Made Bag Packing Machine -...

-

Factory directly Vertical Packing Machine For S...

-

High Quality for Bag Packing Machine For Snacks...